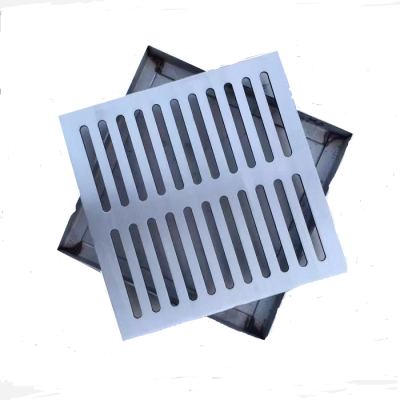

Square Manhole Cover Ductile Iron EN GJS500-7 Solid Top Double Seal

Applications:

Ductile iron castings have been used in almost all major industrial sectors, requiring high strength, ductility, toughness, wear resistance, resistance to severe thermal and mechanical shocks, high or low temperatures, corrosion resistance and dimensional stability. In order to meet these variations in the conditions of use, there are many grades of ductile iron available, providing a wide range of mechanical properties and kinematic properties. Most ductile iron castings, as defined by ISO 1083, are mainly produced in non-alloyed state. Obviously, this range includes high-strength grades with tensile strength greater than 800 Newtons/mm and elongation of 2%. QT500-7, a general-purpose material for ductile iron manhole covers, has a Brinell hardness of 170-230HB. The other extreme is a high-resistance grade with an elongation of more than 17% and a correspondingly low strength (minimum of 370 N/mm scoop. Strength and elongation are not the only roots of the designer’s choice of material, while other decisive important properties Also included are yield strength, modulus of elasticity, wear and fatigue strength, hardness and impact properties. In addition, corrosion resistance and oxidation resistance and electromagnetic properties may be critical to the designer. To meet these special uses, a group has been developed. Austenitic ductile iron, usually called Ni-Resis, is a ductile iron. These austenitic ductile irons are mainly alloyed with zinc, chromium and manganese and are listed as international standards.

Standards and features:

1. high strength. Tensile strength σs≥420MPa, yield strength σs≥300MPa, same as low carbon steel, three times that of gray iron

2. Good toughness. The impact value is similar to that of medium carbon steel, which is more than 10 times that of gray iron material.

3. Good plasticity. The elongation is as large as 7%, which is similar to high carbon steel, while the gray iron steel has an elongation of zero.

4. Strong corrosion resistance. In the water spray corrosion test, the corrosion amount in 90 days is only one tenth of that of the steel pipe, which is one tenth of that of the gray iron pipe. The service life is twice that of gray cast iron, which is 5 times that of ordinary steel pipe.tc.